The Cube offers a wide variety of 3D printers as well as 3D scanners, electronic prototyping equipment, laser cutters, and traditional manufacturing equipment.

Please note that while the following printers are accessible to all students, most have rather high operating costs. Therefore, most projects will be printed on our Dremels. In most applications, these printers produce prints comparable to even our most expensive printers. Nonetheless, our industrial printers will be used for personal projects that show the need.

Which printer is best for my project?

For most projects we recommend one of our Dremel 3D45 printers. They are extremely reliable and are capable of printing at high resolutions.

If you need higher detail or extremely small parts, we recomend one of our resin printers.

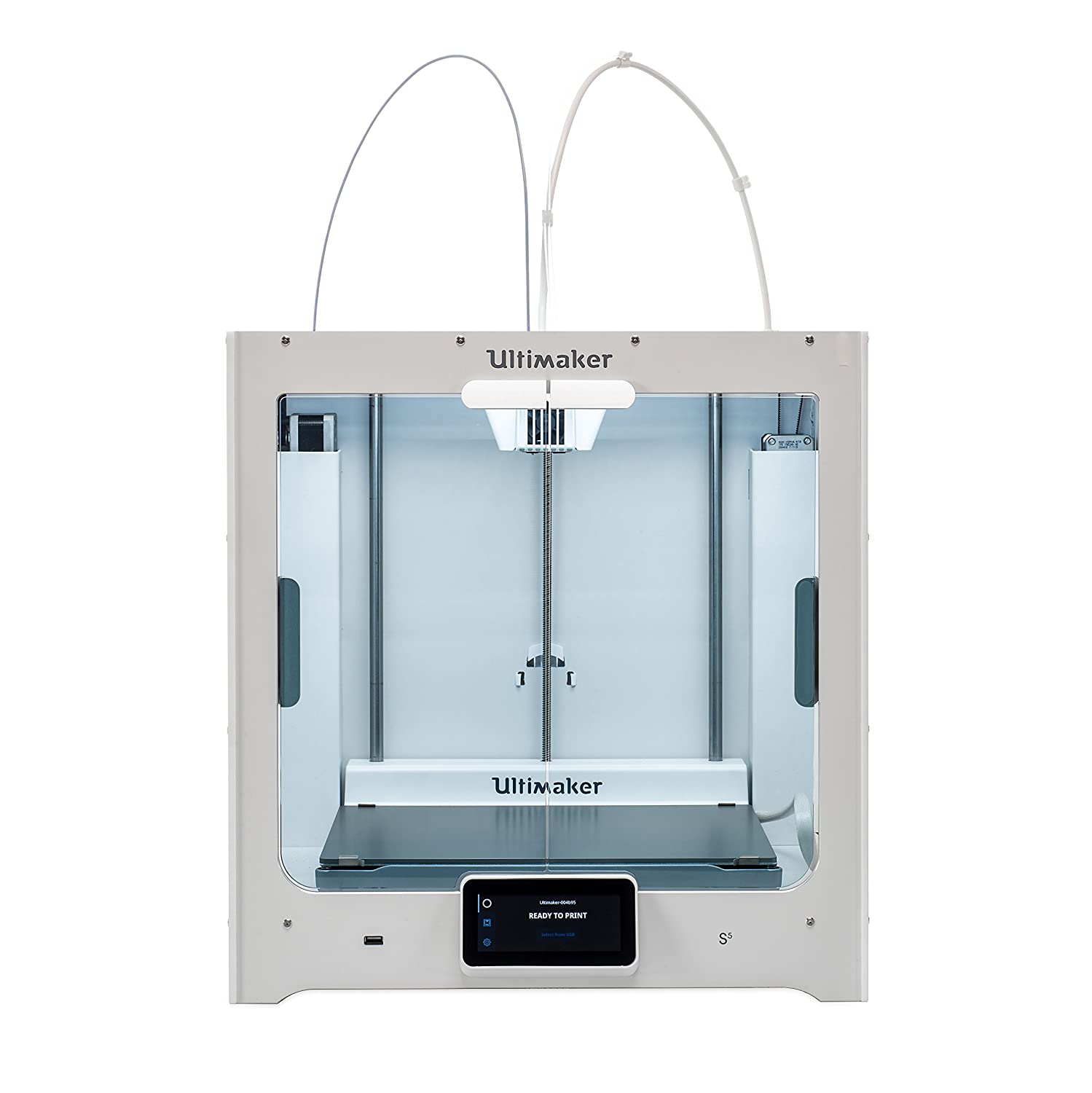

For larger prints, we recomend our Ultimaker S5 or Dimension. The both the Dimension and S5 feature a large print volume and soluble support material.

More questions? Come by 1003 H.M. Comer or email us.

What filament should I choose?

For most applications, PLA on our Dremels is more than suitable.

Alternatively, ABS and Onyx, used by the Dimension and MarkForged respectively, are slightly stronger than PLA and more resilent to heat.

The Cube also maintains small stocks of Carbon Fiber, Kevlar, and other fibers for the MarkForged MK II.

More questions? Come by 1003 H.M. Comer or email us.

Plastic 3D Printers (FFF/FDM)

| Model | Count | Material Compatibiliy | Build Volume | Layer Resolution (μm) | Submission Method |

|---|

| Dremel 3D45 | 8 | PLA | 10" x 6" x 6" | 50 - 300 | 3DprinterOS |

| Ultimaker S5 | 1 | PLA, Tough PLA, PVA | 13" x 9" x 11" | 50 - 300 | 3DprinterOS |

| MarkForged MK II | 1 | Onyx, Carbon Fiber, Kevlar | 12" x 5" x 6" | 100 - 200 | Project Submission Form |

| Dimension 1200es | 1 | ABS, Soluble | 10" x 10" x 12" | 50 - 300 | Project Submission Form |

Resin 3D Printers (SLA)

| Model | Count | Material Compatibiliy | Build Volume | Layer Resolution (μm) | Submission Method |

|---|

| Form 3 | 1 | Resin | 6" x 6" x 7" | 25 - 200 | Project Submission Form | More Information |

| Projet 2500 Plus | 1 | Resin | 11" x 8" x 5" | 32 | Project Submission Form | More Information |

| Form 3L | 1 | Resin | 13" x 7" x 11" | 25 - 200 | Project Submission Form | More Information |

Specialty Printers

| Model | Count | Material Compatibiliy | Build Volume | Layer Resolution (μm) | Submission Method |

|---|

| Blackbelt | 1 | nGen | 13" x ∞ x 13" | 100 - 300 | Project Submission Form | More Information |

| Projet 460 Plus | 1 | Powder | 8" x 8" x 10" | 4 | Project Submission Form | More Information |